wrought iron and modern fences

SEE OUR REALISATIONS ->

WROUGHT IRON AND MODERN FENCES

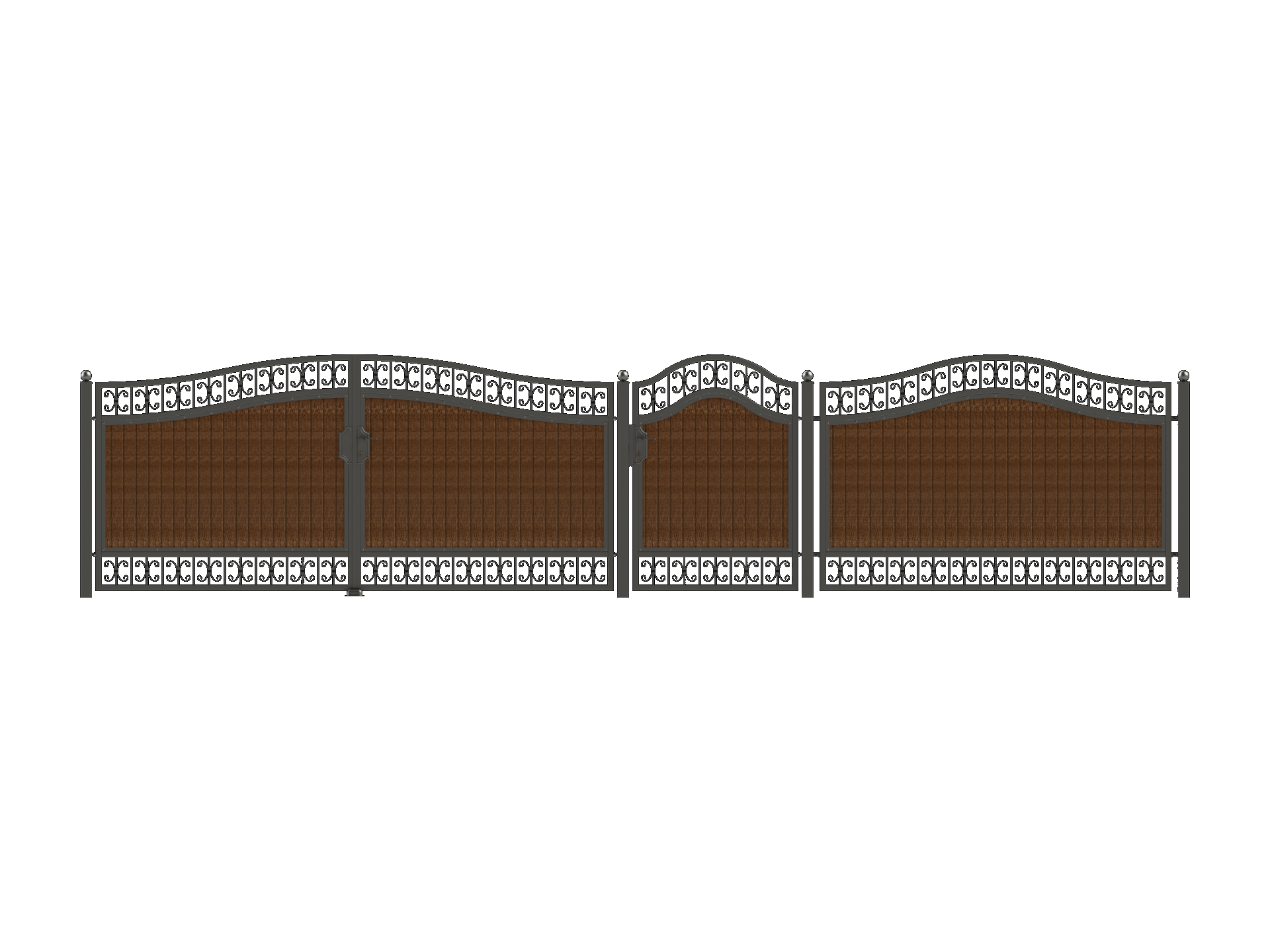

Forged metal fences are one of the most popular ways to fence private properties and public buildings, such as parks, gardens and historic buildings. SZAFRAN company in addition to basic models, which offers adapt to each requirement and imagination of the customer. Thanks to this, each fence, element, span is unique and one of a kind. There is no standard for us.

Each fence is born in a specially prepared computer program, which can eliminate all the errors in the early conceptual stage. In connection with the highest quality materials, it makes our products not only beautiful but also reliable.

FENCE DESIGNS

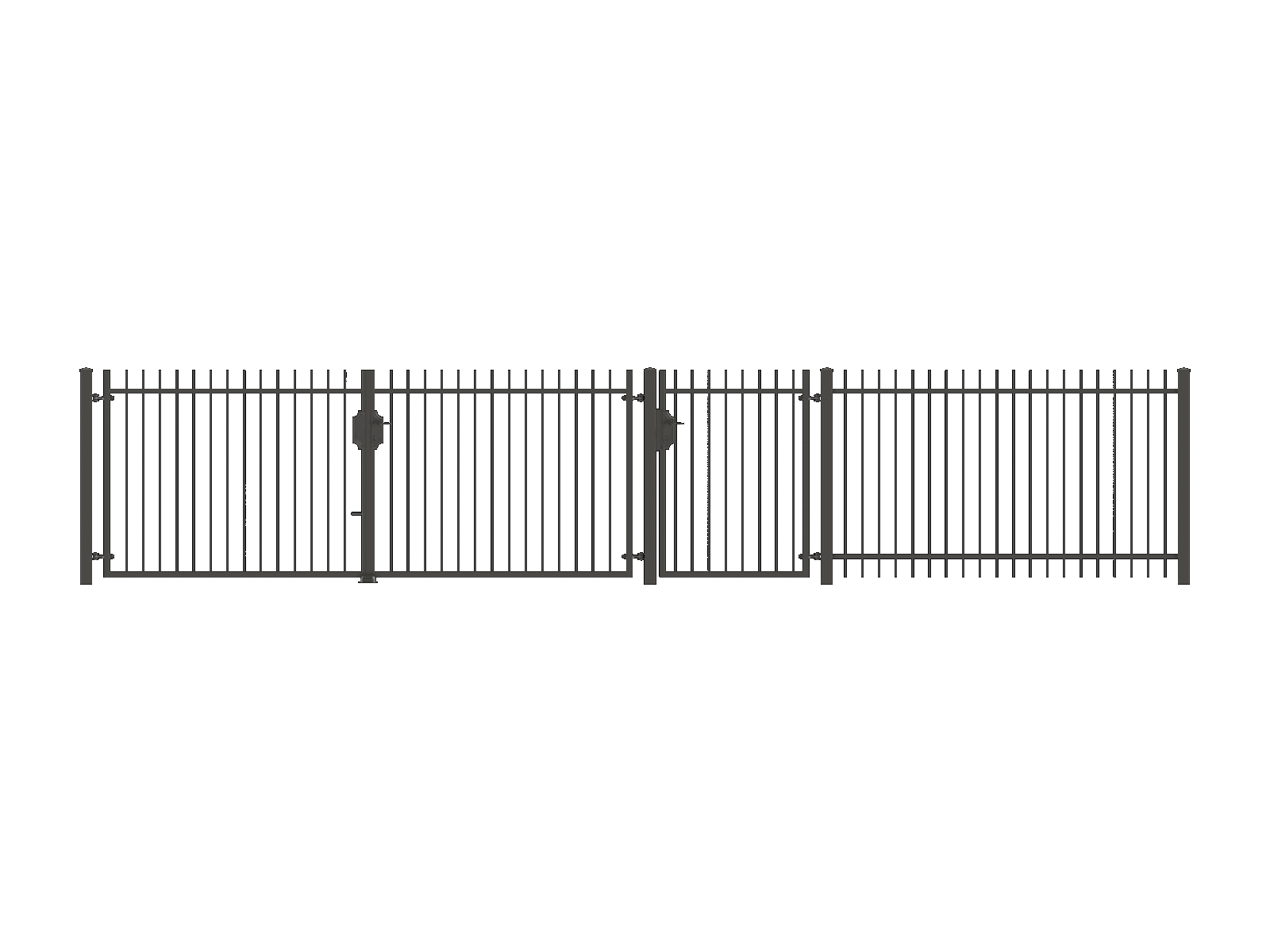

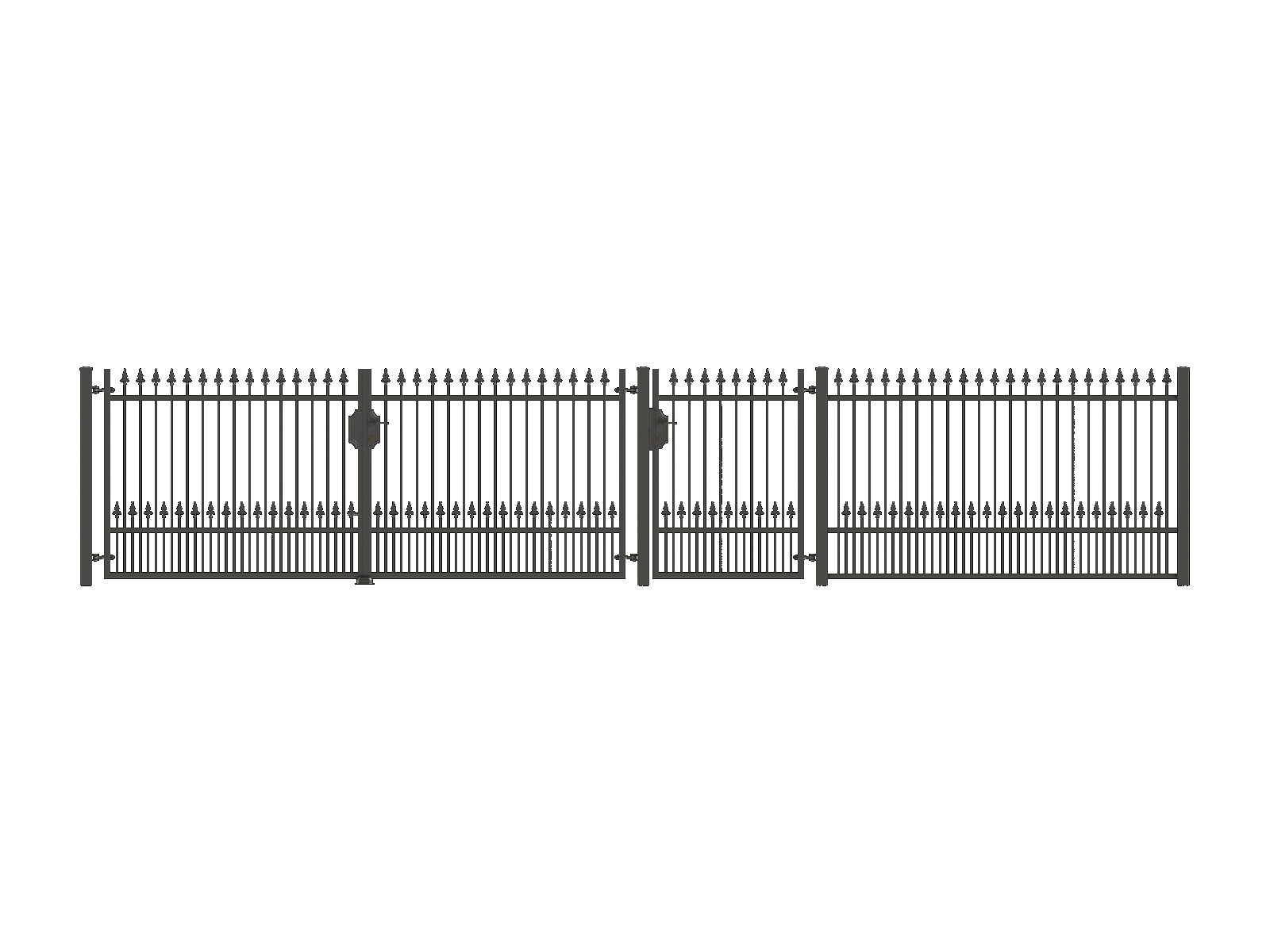

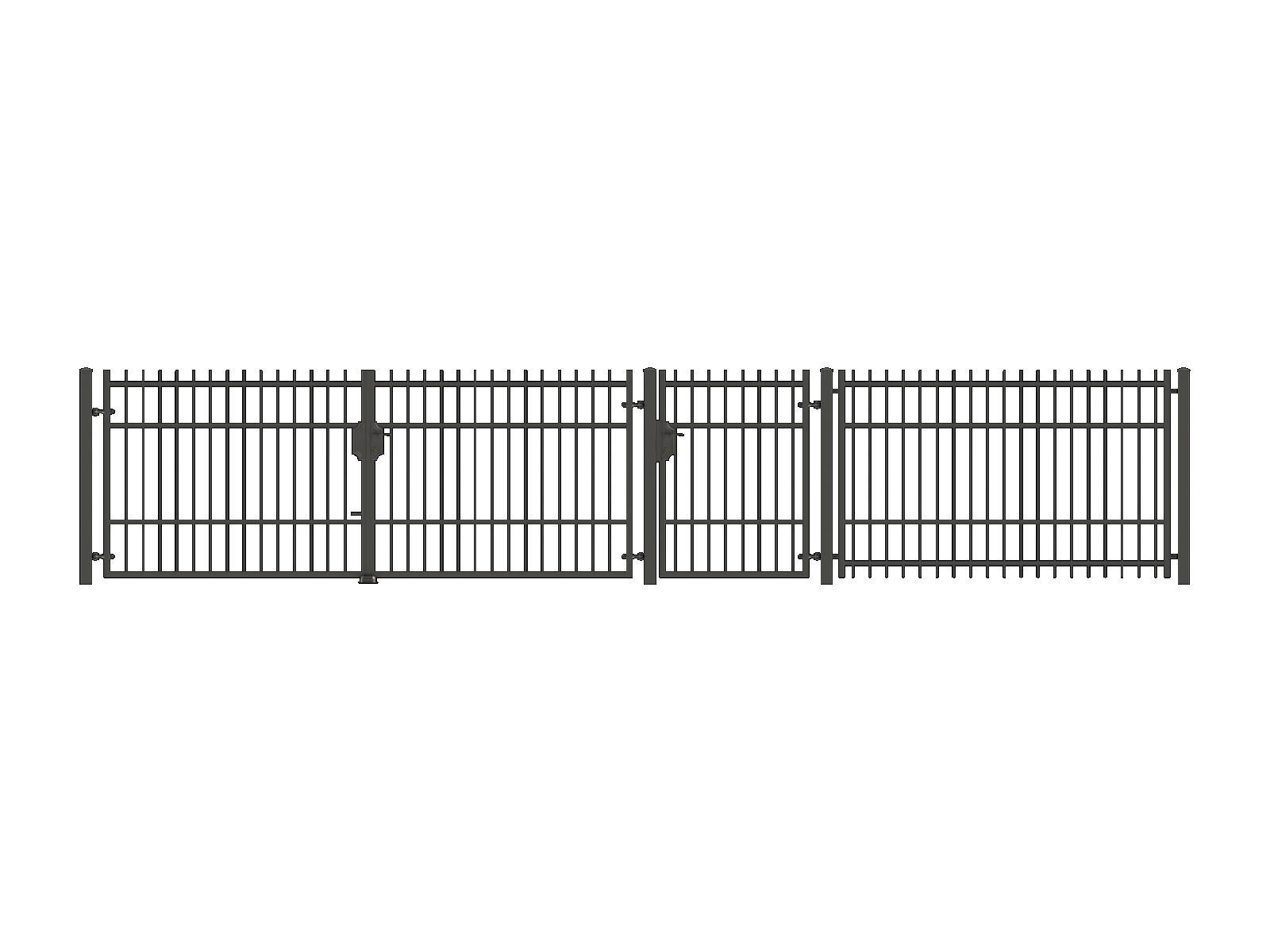

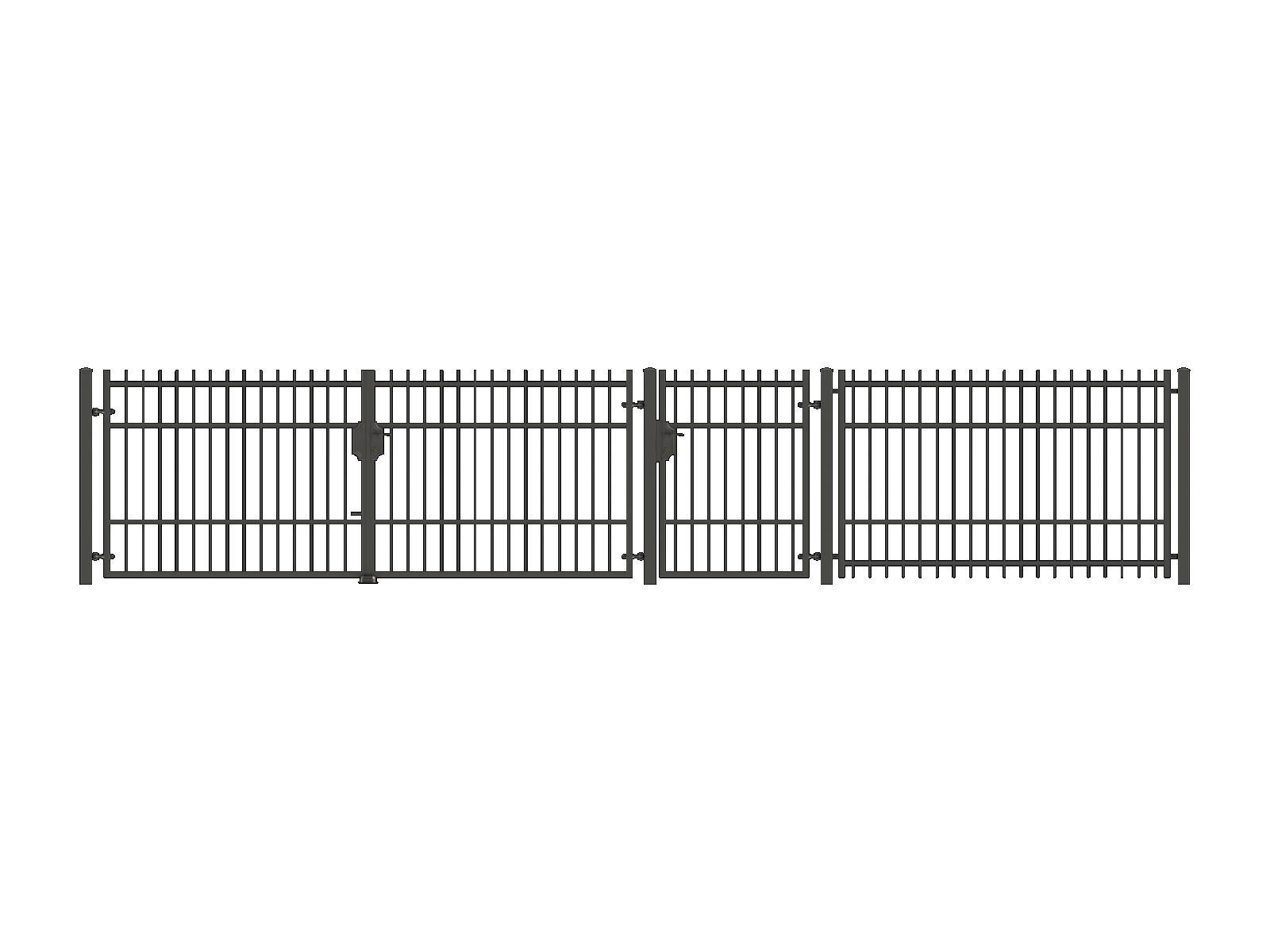

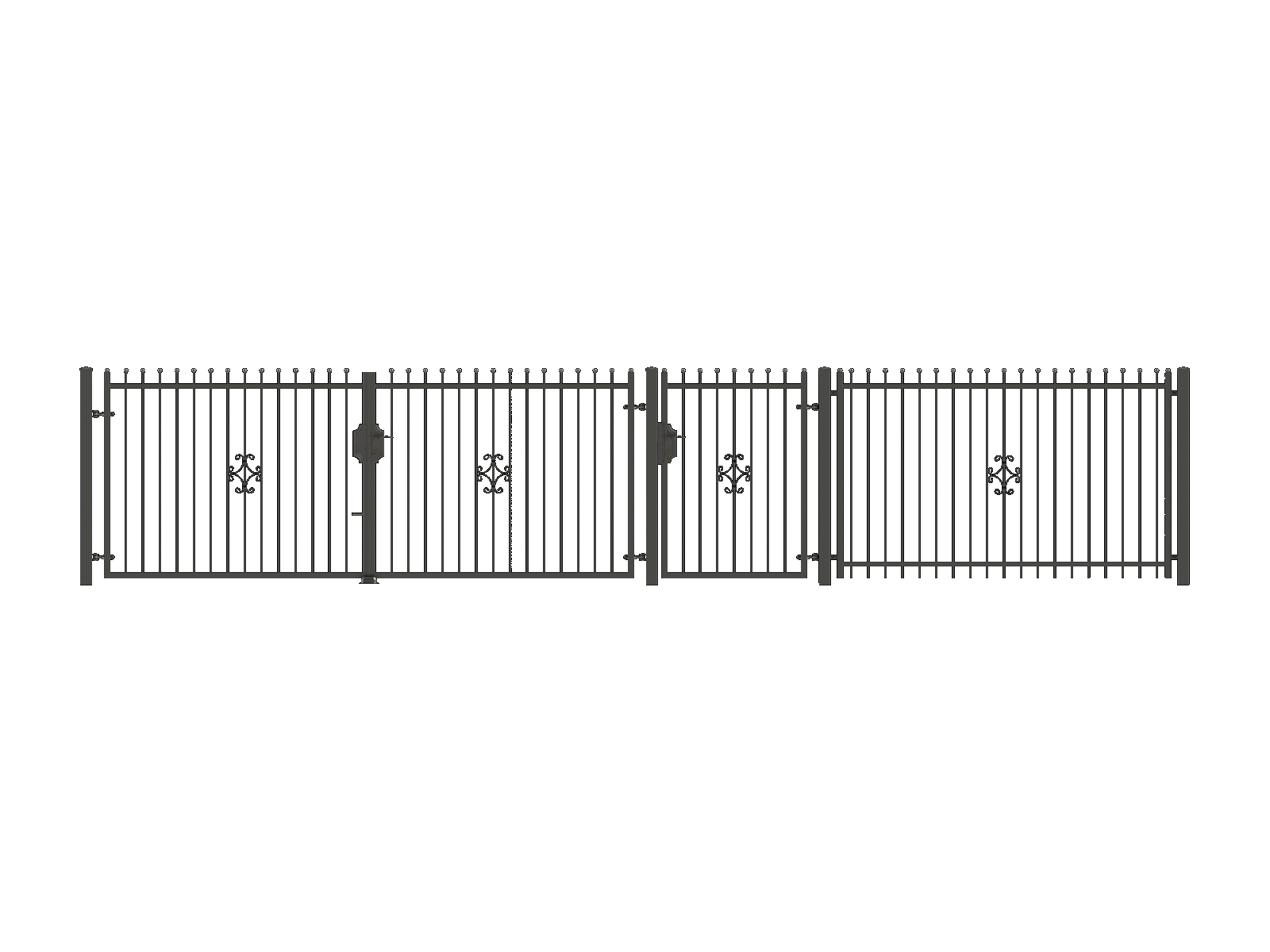

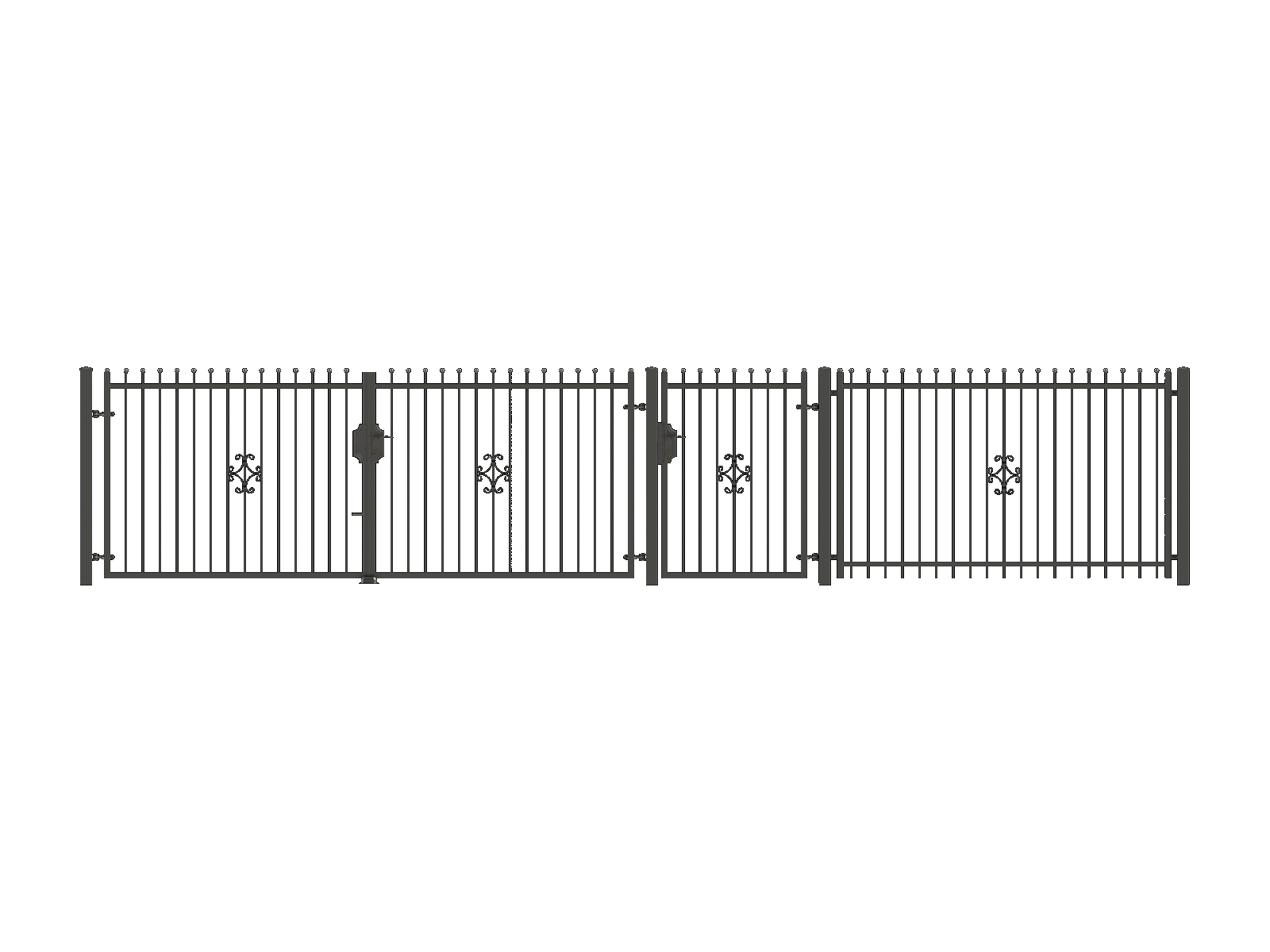

MODEL 5

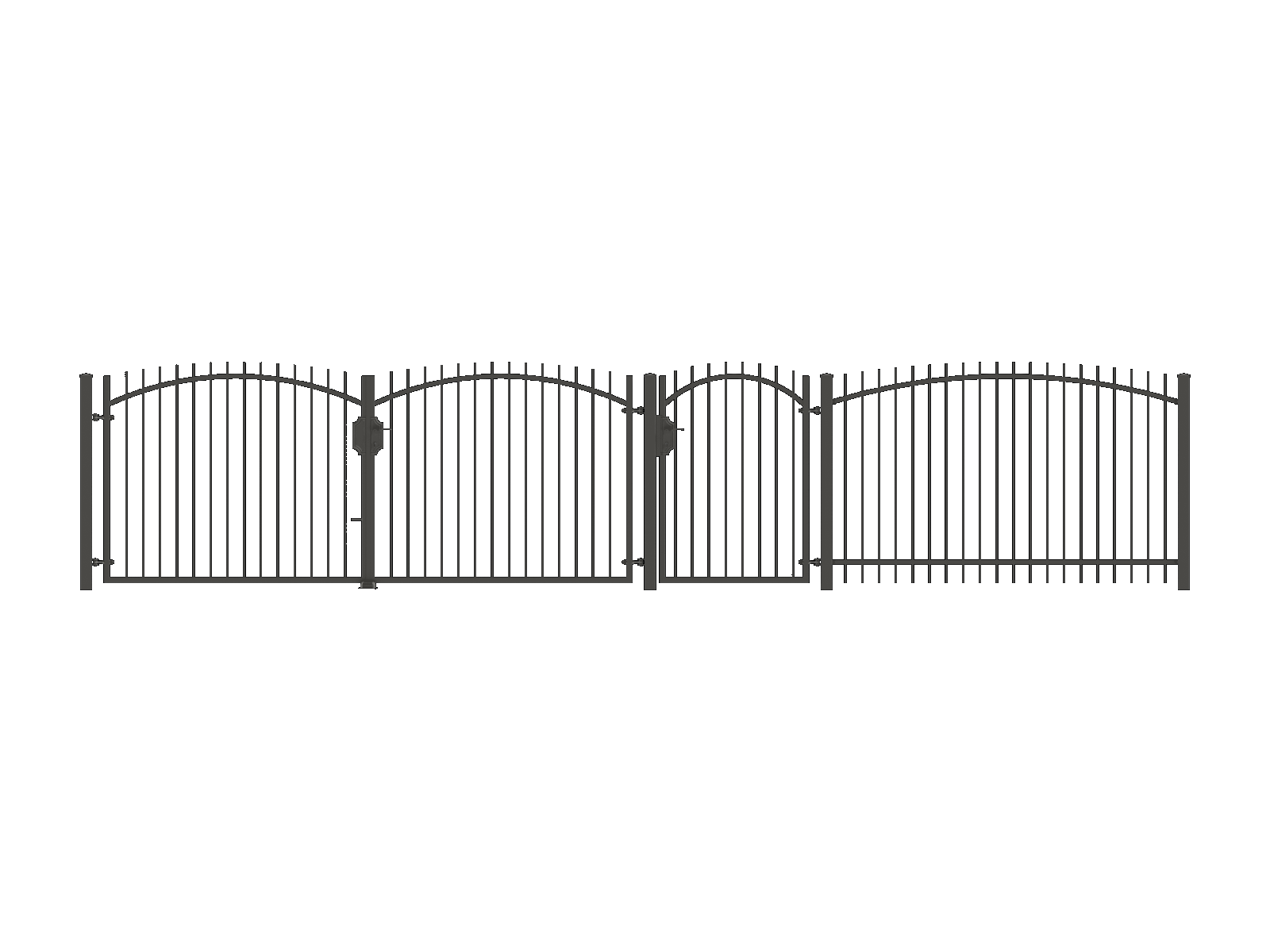

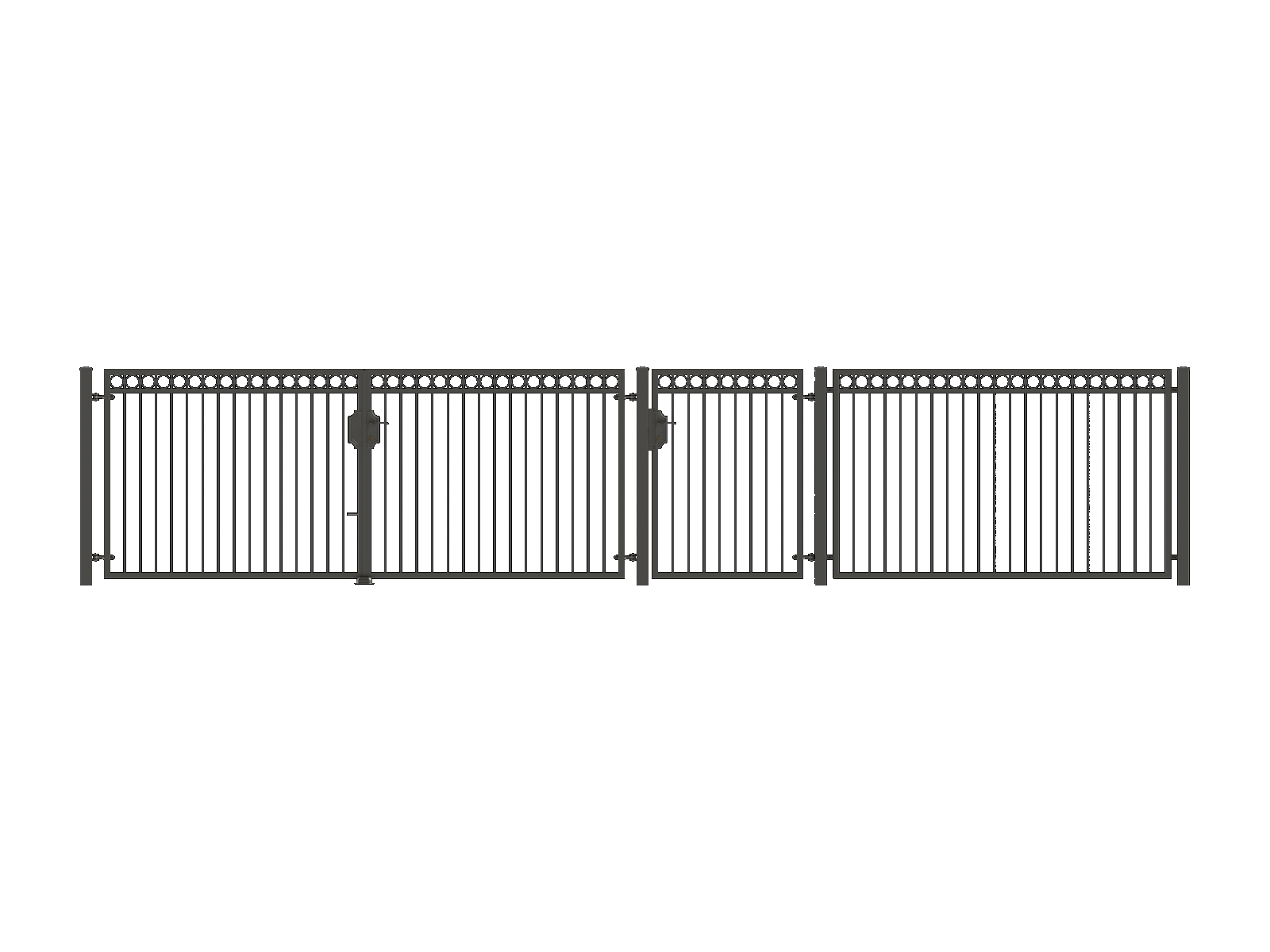

MODEL 11

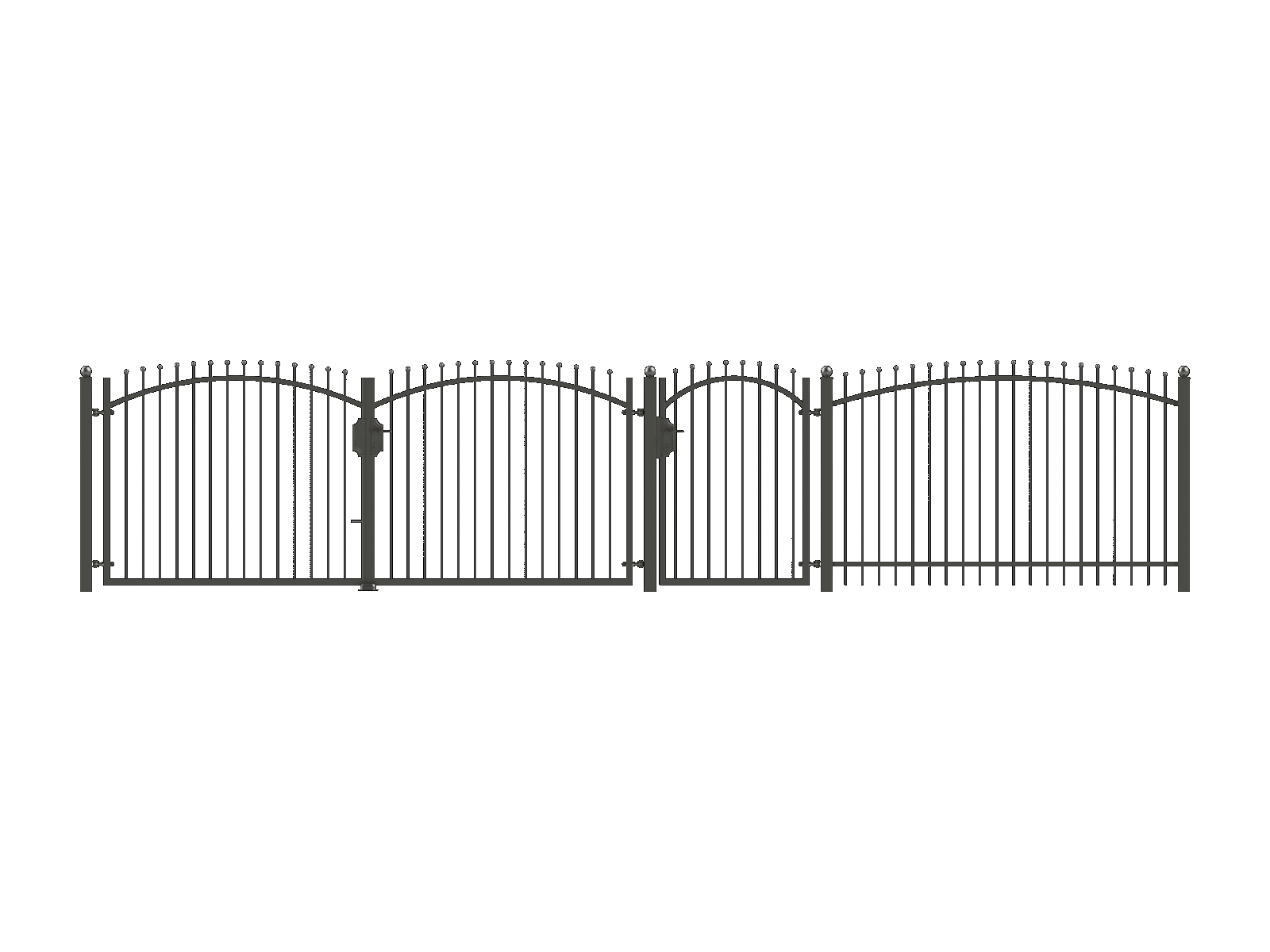

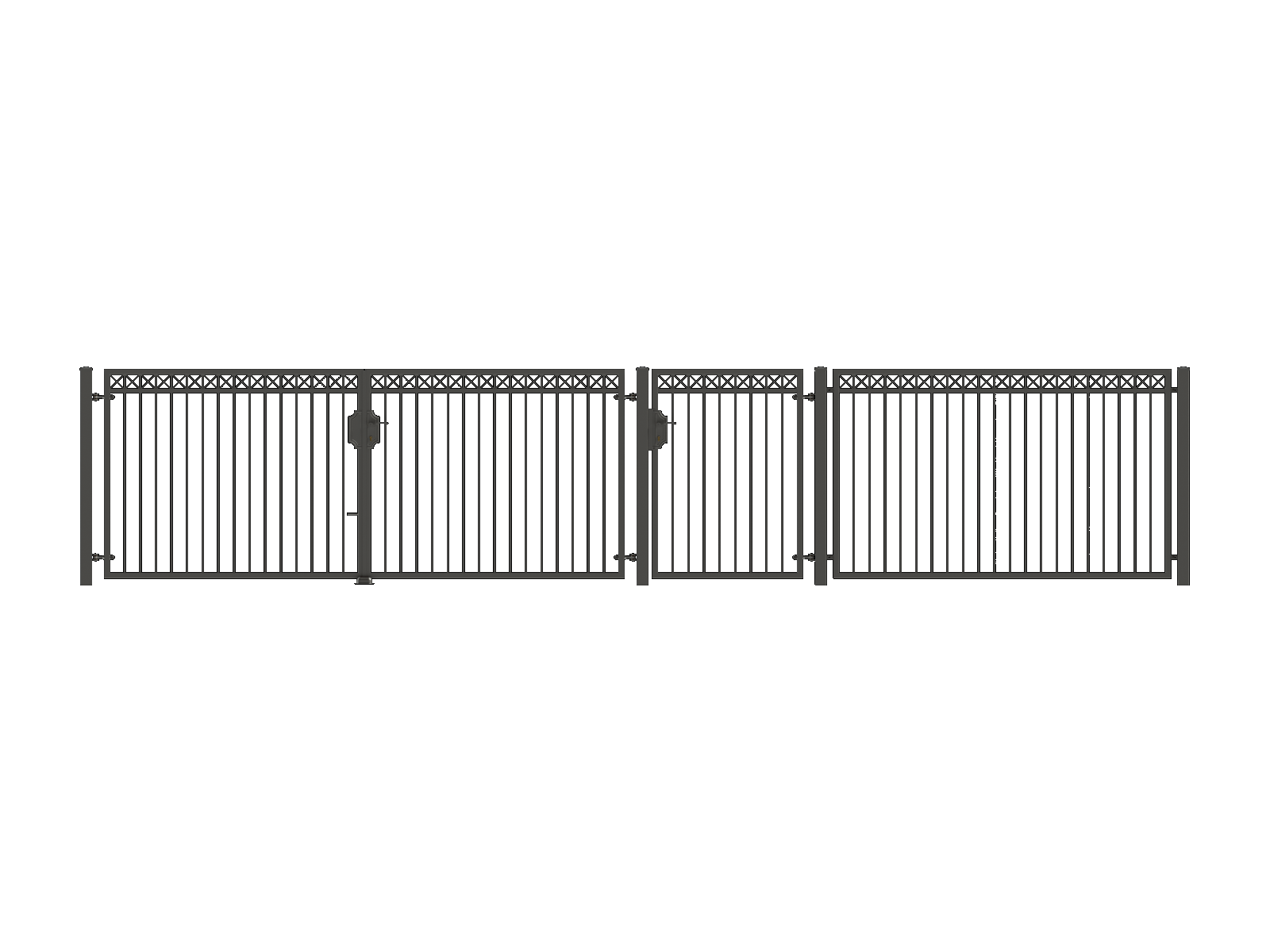

MODEL 13

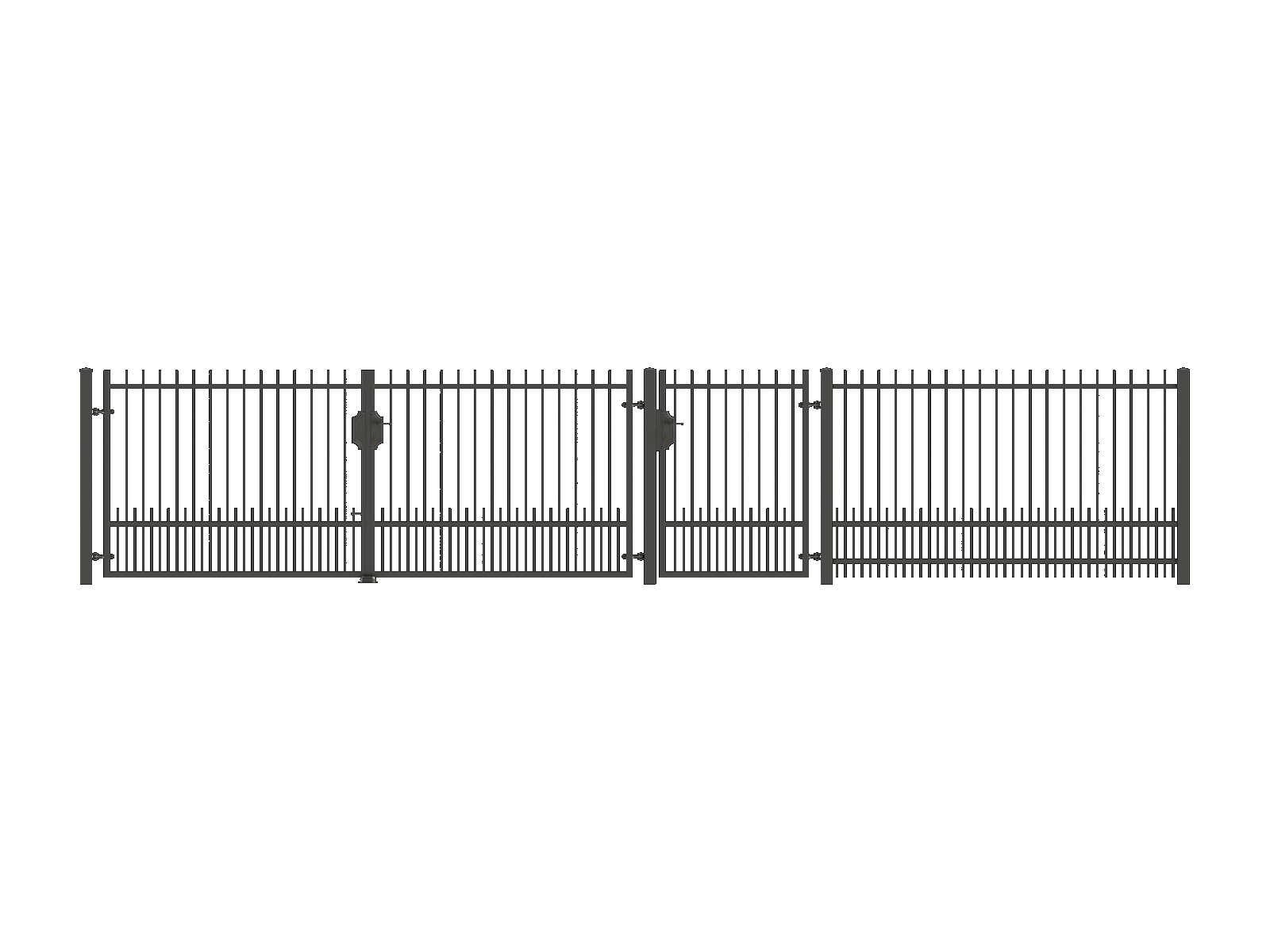

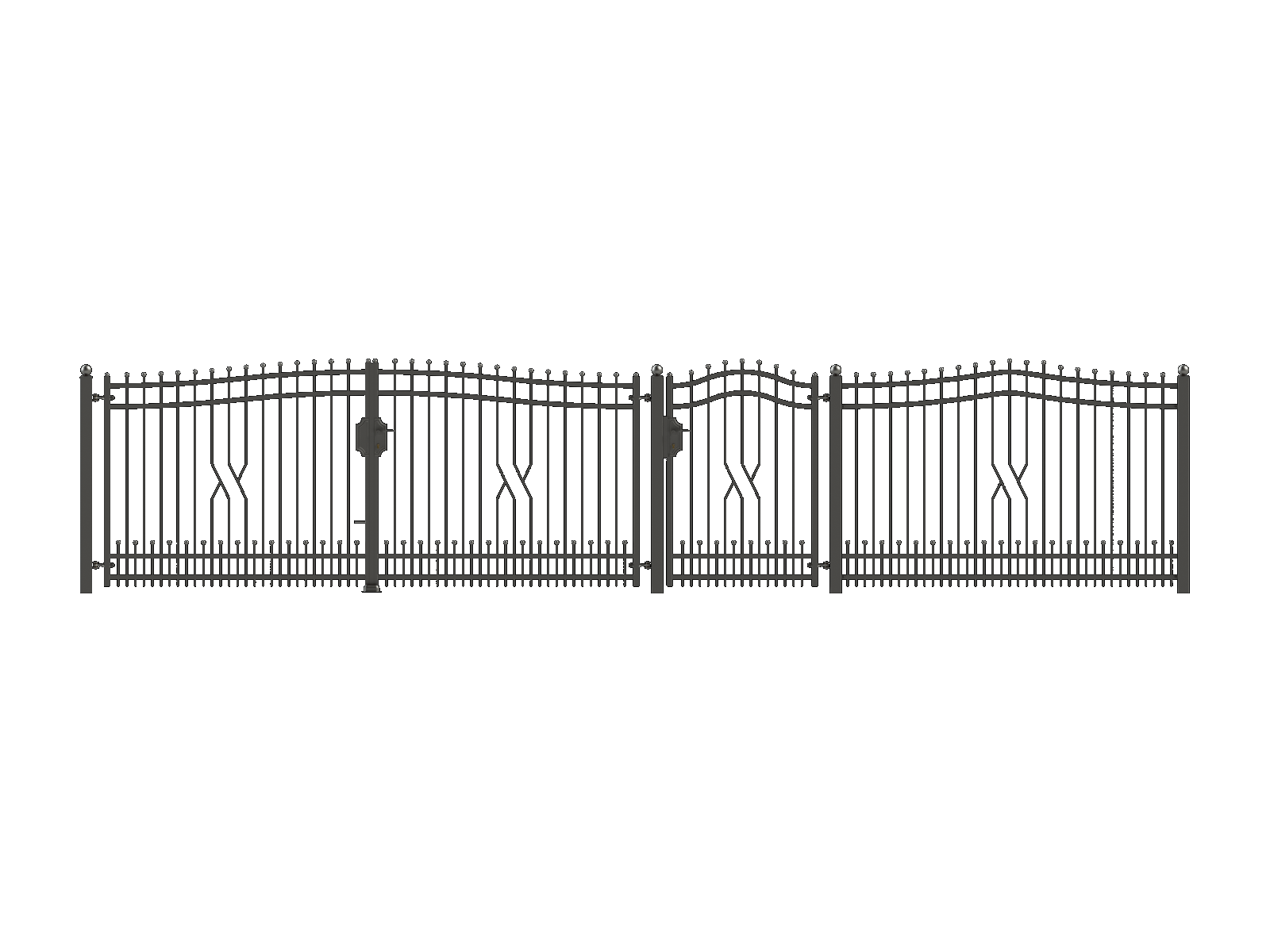

MODEL 17

DESIGN VARIATIONS

All welded fences manufactured by us can be made in the following options:

STRAIGHT

CURVED UPWARDS

WAVE

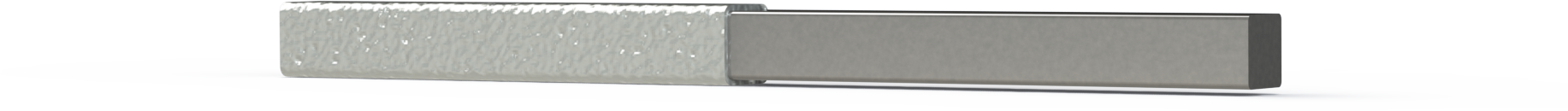

You can also choose the material used

VERTICAL BARS

SMOOTH ROD

CRIMPED ROD

HORIZONTAL ELEMENTS

SMOOTH FLATBAR

CRIMPED FLATBAR

HESPEN FLATBAR

SMOOTH PROFILE

CRIMPED PROFILE

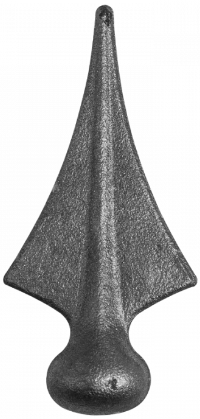

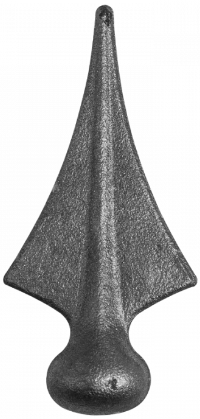

GROTS

GROT G1

GROT G2

GROT G3

GROT G4

GROT G5

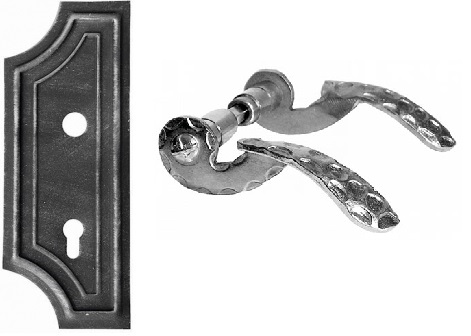

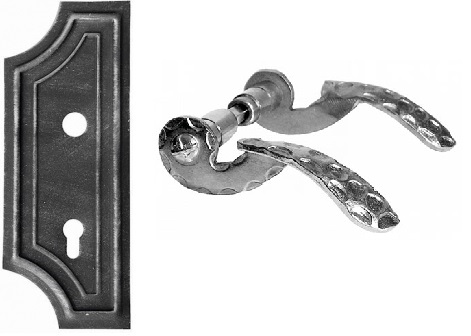

HANDLES AND COVERS

S1

S2

S3

HATS

D1

D2

STANDARD COLORS

To meet the wildest expectations of our customers our fences are painted in any color from the RAL palette. However, we present the most popular ones.

RAL 6005

RAL 7016

RAL 7024

RAL 7040

RAL 8017

RAL 9005

RAL 5010

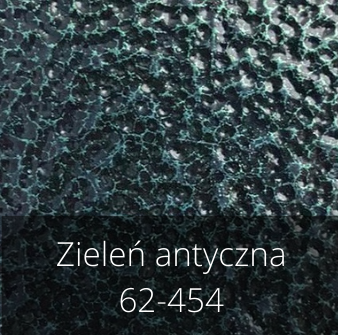

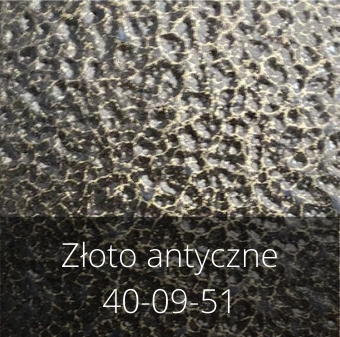

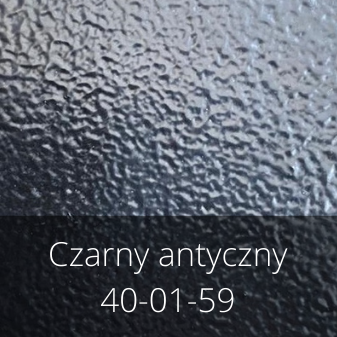

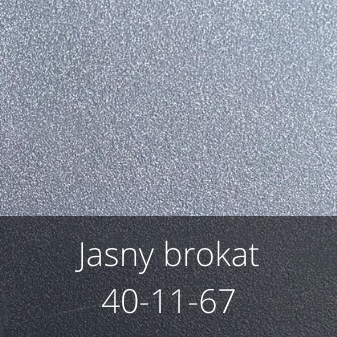

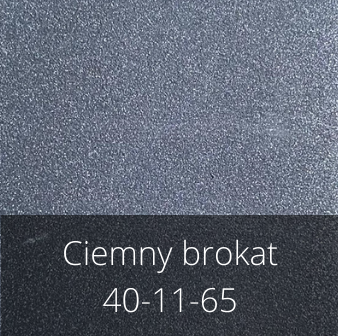

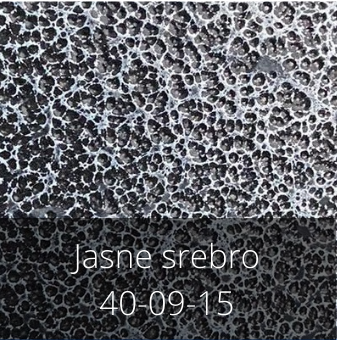

In addition to the RAL colors, we also offer a range of antique and hammered finishes.

HOT DIP GALVANIZING AND POWDER COATING

HOT DIP GALVANIZING

An anti-corrosion coating in the form of hot dip galvanizing is applied on fences. This is a multi-stage process consisting of:

etching and washing in order to clean the element

immersion of the element in a solution of liquid zinc heated to 450-460°C.

During the controlled chemical reaction, a strong bond between the zinc particles and the steel is formed, which results in a corrosion-resistant and durable coating with a thickness of up to 50-70 µm and a durability of up to 50 years.

GALVANIZING + POWDER COATING

Previously galvanized fence elements can have an additional coating in the form of powder paint. The process consists of:

washing in a special chemical solution in order to clean the element

rinsing with demineralized water

applying an anticorrosive passivation

powder paint coating application with applicators of the renowned company GEMA

polymerization at a temperature of about 200°C creating a coating resistant to impacts, corrosion and weather conditions

The undeniable advantage of powder coating is a wide range of colors from the RAL palette, large availability of structures (smooth gloss, fine and coarse structure, hammer effect), the speed of the process, high quality of the resulting surface.

SEE MORE

Registration Data:

Szafran Zaune aus Polen Sylwia Szafran

Kresowa 84 B Str.

66-620 Gubin

VAT ID: 743-19-71-781

REGON: 365945686

Production plant:

Kresowa 84 str, 66-620 Gubin